Technology

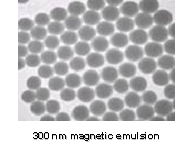

At ADEMTECH, our proprietary technology ensures a highly reproducible manufacturing process for producing calibrated magnetic emulsions. By controlling fragmentation through precise shearing techniques, we are able to create uniform magnetic emulsions ranging from 100 nm to 500 nm in size

Our nanoparticles exhibit superparamagnetic behavior, meaning they display magnetic properties only when exposed to a magnetic field, and no residual magnetism remains once the field is removed. This ensures both efficiency and precision in applications requiring magnetic separation.

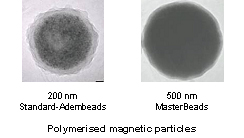

ADEMTECH has developed an in-house polymerization process that efficiently isolates the magnetic core, offers tunable functionalization, and provides exceptional colloidal stability.

The polymer provides the magnetic core with a uniform protective shell in order to isolate iron oxides that can interfere with some enzymatic reactions.

(as shown on Transmission Electron Microscopy photos)

Our nanoparticles feature a hydrophilic surface designed to minimize non-specific protein interactions, enabling precise applications in life sciences. With a high magnetic content exceeding 70%, even the smallest particles achieve rapid and gentle magnetic separation using a simple magnet.

ADEMTECH has perfected simple and reproducible protocols for coupling proteins to nanoparticles. These protocols result in high binding capacities, reduced non-specific binding, and long-term stability, ensuring optimal performance in various scientific and diagnostic applications.

When exposed to a magnetic field, ADEMTECH’s magnetic particles self-organize, allowing for gentle separation without the need for complex equipment like columns or centrifugation. This streamlined process maximizes efficiency while maintaining the integrity of your samples.

ADEMTECH - BioParc BIOGALIEN - 27 allée Charles DARWIN - 33600 PESSAC - France

Phone: +33(0)557.020.201 Fax: +33(0)557.020.206

© 2024 Ademtech. All rights reserved.

All content and images used on this site are owned or licensed by Ademtech for use on this site only. The Ademtech Logo and Ademtech pictures are trademarks of the Ademtech group of companies. Unauthorized use is prohibited.

This website is governed by applicable France laws and governmental regulations.

The products and information contained may not be accessible in all countries, and Ademtech takes no responsibility for such information which may not comply with local country legal process, regulation, registration and usage.